how to test steel hardness with a file|metal dented after hardness test : purchaser One difference between hardness testing steel with files and the Mohs scratch hardness test, is that with the Mohs you are testing one material or mineral against another. With the file test you are testing steel against steel, . Resultado da 11 de fev. de 2024 · Goblins Cave Slot Demo - Redstar BetMelhores slots para ganhar dinheirojogos de azar argumentos a favorcomo jogar hilobetano promoções. Joinville, uma cidade localizada no estado de Santa Catarina, tem se destacado como um importante polo industrial e tecnológico do Brasil. .

{plog:ftitle_list}

WEB20 de set. de 2023 · » ‘Os Mercenários 4‘ também apresentam uma série de novos atores: Andy Garcia, Curtis Jackson, também conhecido como 50 Cent e Tony Jaa.

One difference between hardness testing steel with files and the Mohs scratch hardness test, is that with the Mohs you are testing one material or mineral against another. With the file test you are testing steel against steel, .

However, I have found that you can roughly estimate the hardness to within about 2 1/2 points by judging how easily the file digs in or skates on the steel. Amazon also sells . An easy-to-use, dramatically less expensive alternative to a Benchtop Hardness Tester, the TTC Hardness Tester File Set allows you to quickly ascertain the hardness of your material. Wat. I'm not sure what this device is called but there is a cheap hardness tester you can purchase that uses a graduated glass cylinder and a hardened steel ball. The height of the . Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Various hardness testing .

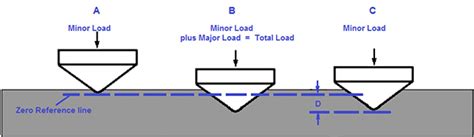

Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

These files are generally unsuitable for anything that would require a particular hardness, like a knife, blade, or hard tooling. Ultimately, though, you’re likely dealing with a mystery metal. Read on for a few tips and tricks, like how to . So which actually works best, when selecting from a bunch of similar steel ?Camera: Nikon L820

A hardness test uses a limited compressive force to apply a small deformation to the surface of a material, in order to assign a relative value for the material’s hardness. However, a ductility test uses a destructive tensile force to measure the amount of plastic deformation that a material can withstand before breaking.

Brinell Hardness Test: The Brinell hardness testing method is commonly used to test large or coarse-grained materials like nonferrous metals, castings, and forgings. This hardness testing involves applying a known load to a spherical indenter, typically made of hardened steel, although a tungsten carbide ball may be used for harder materials.Measuring The Hardness Of Steel. Traditionally, a metal file or a sharpening stone was placed at the edge of a material to gauge its hardness. Nevertheless, this procedure was highly subjective and yielded uneven results every time. There was a need to devise a procedure to test hardness with accuracy and repeatability. We are hardening some steel products and needed a way to verify the final hardness. Hardness testers are very expensive. This set of files made by Tsubosan i.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly.To get the right steel for the intended application, quality knife manufacturers prescribe a specific steel strength. Then they test it to ensure the blade meets an exact number on the Rockwell hardness scale. Who Uses the Rockwell Hardness Scale and Why. Every American steel product manufacturer uses the Rockwell hardness scale. Each of the files is of a different hardness, so it is possible to roughly gage hardness by which ones cut and which ones don't. I doubt the accuracy is any better than, say, plus or minus 3 to 5 Rc. That said, this is about as good as the cheap bounce testers and a lot more flexible in use (part doesn't have to be massive, flat shaped, etc.

The file test is just for directly after quenching, I believe. If the file "skates" off the steel, it got hardened, and you can proceed with the tempering, etc.. I'm not sure if the file will still skate after the steel is properly tempered. ..but you're right, that's basically it. The File Test. The File test is an excellent way to provide with you an idea of relative hardness. To successfully do this test, you must first heat the piece of metal and quench it. Heat the piece until it reaches non-magnetic temperatures and after that immediately quench it in either water or oil.The file test is a less precise test of hardness. The file test is a method of determining the hardness of a piece of material by trying to cut into it with the corner edge of a file. The hardness is indicated by the file bite. . A “C” scale . Flexbar Hardness Testing Files.Easy To Use, Portable Rockwell Hardness Testing System for Use in All Metalworking Facilities. Flexbar introduces a unique new Set of six Specially shaped files, each With a non .

How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating..Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

Brinell hardness. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer the material, the deeper the ball will penetrate and vice versa. The next step is to take a measurement of the diameter .Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file. A video for knife making tool geeks. I think these Rockwell hardness test files are an essential part of your shop when you start heat treating tools and kn.The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force.For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation .

With the increasing use of materials other than common steel and brass, as well as requirements to test thin materials and sheet steel, a basic knowledge of the factors that must be considered in choosing the correct scale to ensure an accurate Rockwell test in necessary. . For the lowest hardness test force, the 15 Kgf scales, a polished or .

types of hardness testers

Tsubosan Steel Hardness Test kit. 51 Bravo Custom Knives . Videos for related products. 1:05 . Click to play video. Fowler Full Warranty 52-760-000-0 Hardness Tester File Set. Merchant Video . . Using these hardness files to test hardness of annealed and heat-treated tool steels in my shop. Measures Rockwell C-scale hardness within a few .You can get a set of files that are made to check hardness. Can't find a link right now, as I'm on mobile, but check out MSC. Reply killabeez36 • Additional comment actions. Find a piece of steel or metal that you know to be harder than whatever it is you're trying to test. Then get a ball bearing and sandwich it between your two different .

Roy is trying out the Amazon hardness tester file set. These hardness test files are a type of hardness testing equipment. These hardness test files are avai. Common tools to test a mineral’s hardness are a fingernail, Cooper wire or coins (penny or 1,2,5 cents euro), a knife, a piece of glass, and a steel file. Additionally, a set of minerals with a known hardness can be used.

custom general mmd7np non invasive moisture meter

web18 de nov. de 2023 · Pou Sound Variations/Variações de som. Pou Vlogs. 137K subscribers. Join. Subscribe. Subscribed. 560. 113K views 2 months ago #pou .

how to test steel hardness with a file|metal dented after hardness test